Nazhoen Pelri Eco-Friendly Initiative

A Featured Investment Project and Social Enterprise

As an innovative social enterprise of the YDF, the Nazhoen Pelri Eco-Friendly Initiative in Bjemina, Thimphu is Bhutan’s first ever waste paper recycling unit that produces on average 20,000 egg trays per week from waste materials and employs recovering drug dependent youth to reintegrate them into society. Income from the unit also supports and sustains the Drug Education and Rehabilitation Services program of the YDF.

The project is working to achieve the following objectives:

- To preserve the natural environment through waste management and recycling in urban areas;

- To reduce the rapidly rising youth unemployment rate;

- To empower, train, and reintegrate recovering drug dependent youth;

- To reduce the import of foreign goods and build a self-reliant Bhutanese economy;

- To contribute to the development philosophy of Gross National Happiness, in particular, the two pillars of (1) equitable socio-economic development and (2) conservation of the environment.

Impact:

- Environmental: The unit promotes waste management efforts for a greener, cleaner environment and recycles waste paper collected in urban areas. In an hour, the unit produces approximately 720 egg trays from about 47kg of waste paper, thus producing 3,500 to 5,000 egg trays every day. Producing up to 1.3 million trays per year, the plant recycles approximately 100 tonnes of waste paper, thus reducing and reusing that much waste annually. It also removes 165 tonnes of carbon dioxide (CO2) out of the atmosphere by reducing the need to use fossil fuels to transport egg tray imports via truck from India.

- Social: The unit offers reintegration and post treatment services to unemployed, recovering drug dependent youth by hiring them on an annual (rolling) basis. This provides work experience and prepares them for reintegration into society after the successful completion of the treatment program at YDF’s Drug Rehabilitation Center.

- Economic: The unit produces egg trays for Bhutan, in Bhutan, thus retaining economic value in country and reducing overall imports from neighboring countries. This builds a more self-reliant and robust local economy. Meanwhile, income from the unit sustains the YDF’s important youth programs as a non-profit civil society organization.

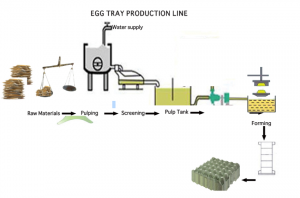

Process:

After soaking the waste paper raw material in water to soften them, they are then turned into a pulp and filtered for foreign materials like plastics and pins. The filtered paper pulp is stored in a tank and pushed through a pipe into an egg tray-molding machine. The pulp that spills over is transferred back to the tank. The wet egg trays are dried on trolleys or by machine. They are then prepared and packed for sale.

News Coverage:

Partners:

Greener Way

Karma Feeds (Karma Groups of Companies)

UNDP-GEF Small Grants Programme

Goodwill Community Foundation